Ah, yes... its been awhile since I last posted. Sorry about that. I do have some valid excuses reasons! I had the issues with my feet and that took time to resolve, then there was the week long migraine I dealt with..... and just when things started to look good, I pulled a muscle in my mid back. Seems the old gal isn't aging well... yup, another birthday has come and gone and lets say I'm entitled to all senior benefits now.

So lets get down to weaving which is why you really come here and not to hear me whine. 🍷 Anytime in the past when dealing with a newbie weaver I have always stressed the importance of planning for success. That weaving starts with a pen and paper. You have to know a few things in advance:

- what you want to weave and its end purpose.

- what yarn do you plan to use; what size, colours etc.

- how wide and how long?

- can your loom handle the width?

- do you have the right size reed?

So lets use my runner project being shown here today. I wanted to use 10/2 mercerized cotton. The recommended sett is 28 epi for a twill. I used a 12 dent reed and will dent it 2, 2, 3.

I'd like the runners to be 15 inches when all finished so I adjusted my 12 shaft draft to be 492 warp ends and so 17.6 inches in the reed. This allows for draw in and shrinkage.

I wanted to weave three runners where the main portion will measure: one 36, a second 45 and the third 55 inches in final length. I want them to be hemmed and I particularly like a wider hem allowance and so planned for 6 inches either end x 6 hems. I plan to do ladder hemstitching and have a slippery thick cord on hand for the spacer.

I allow 12 inches for a project sample for my records.

Now that I have all the woven portions of my project planned, I calculate the take up. I allow 3 inches for every yard woven.

Only then do I add in the loom waste.

So my rough working notes looked something like this:

492 ends divided by 28 epi = 17.57 inches in the reed (Project width)

Project Length:

3 runners (36, 45, 55 inches for length of main portion of runners) = 136 inches

hem allowance (6 inches x 6 hems) = 36 inches

sample = 12 inches

Take up allowance of 15 inches (136 + 36 + 12 = 184 inches, divided by 12 = 15.33 feet divided by 3 = 5.1 yards) Allow 3 inches for each yard so add another 15 inches.

Now add in loom waste of 20 inches (based on my loom) Still with me here? 😊

That comes to a grand total of 219 inches

Divide by 12 = 18.25 feet

Divide by 3 = 6.08 yards I went with 6.5 yards.

I measured my guide string and put it on the warping mill and again planned to make 4 bouts of 123 ends. This makes it more manageable to wind and to beam later. I also added two additional ends as floating selvedges.

Now and only now do I start winding my warp. This comes last after all the paper work and number crunching. Its not very glamorous like the 'throw the shuttle part'.... but I call this part weaving too. If you think of it this way, then it becomes an integral part of the whole experience.

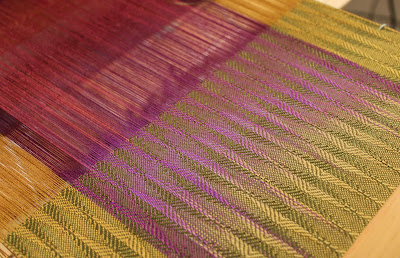

So the project is finally loaded on the loom and under way. You can just see the hem allowance and my hemstitching.... then the start of the pattern. I took a picture of this part right away. Why? So I have a visual reference of what I did so I can finish it at the other end in the right configuration. Reverse the pattern in the hem allowance so its like a mirror opposite. In the past if I have not taken good notes of what steps I have taken, I have had to unroll the cloth beam and see what I had previously woven at the start and then try to rewind again. It doesn't always go well. So this picture step is something I added to make life easier for myself. Also it has the additional bonus of showing you any threading errors before you go too far!

I don't know the how or why of it, but our eyes want to see symmetry and will skip over the errors no matter how hard you search.... but take a picture, and they stand out clear to see (especially if you have shared it on line 😳)

The draft is a 12 shaft turned satin weave that came to me by way of a friend in Scotland. Its a lengthy repeat and you had to really pay attention. I made little cheat sheet on a lined post it note of the repeat and slide a little alligator clip from line to line as I go along. If a line between blocks looked a bit strange on the loom, then you have missed a treadle step at the transition. Go back and fix it ! Errors are mistakes, NOT design elements.

I experienced some tension issues on the right hand side of the warp and so made the first runner my 36 inch one and cut it off the loom. Re-tensioned correctly and started again. This meant my loom waste just became more than what I planned so there went my sample! My records now have a picture instead.

Once I had woven the final two runners, they came off the loom and go straight into the finishing phase. I'm not a fan of a 'project pile'. I serged the runners apart and then put them into a warm sudsy soak. Rinsed and then I spun them out in the washing machine using the spin cycle only. Pulled them into shape and smoothed and hung on a drying rack over night.

The next morning I carefully snipped all weft tails and then used my steam press to smooth the cloth. Then I used an iron to press again and turn the hems. Divide the hem allowance and turn twice and press firmly and pin. I turn it right at the base of the hemstitching. Then I hand sew the hems; both ends are closed and one tiny running blind stitch to each and every 'ladder'. This gives you a very neat finish and the runners are reversible.

Yes, its a lot of work....there's a lot pressing / ironing but its so worth it. You are setting the threads into their forever positions. Future pressing will not be so intense as this.

10/2 tencel weft in a pale gold that I call Honey Gold. The hem was given another press in the Singer steam press to flatten the hem after the hand sewing. All the shrinkage was done before hemming so it will lay flat.

The final width on the runners? Planned was 17. 57 inches at the reed..... they are 15 1/2 inches finished. Pretty close huh?

These runners would look so much better if I had a darker wood table, but maple will have to do!

A peek at the reverse side.... and you can see how the hem allowance looks neat on the reverse.

The last runner was woven with a 10/2 tencel called silver, which I call Grey Mist. It measures 62 inches over all. I think you can see the lovely soft drape?

Here's the reverse of the Grey Mist runner.

So if you are a new weaver or a lapsed mature weaver I heartily recommend that you plan for success and slow the whole process down. Newbies are in a big hurry to get by the 'boring bits' and rush a project to completion. Then they rush another warp on. Its all a lot of work and I'm sure you want it to look its best? Take time over the small details. They really matter.

Above all, no winding a warp and then go looking for a draft to fit it! That's the cart before the horse....

This post is dedicated to hand weaver and author Virginia West who wrote "Finishing Touches for the Handweaver" which set me on the path to giving my projects the elegant finished look. She passed away this week and many weavers the world over collectively thank her for her book, her seminars and workshops over the years.