Thank you for patiently waiting for something weaving related. My back is slowly improving and I'm able to do more, but that's the rub! I have to resist doing more and setting myself back. I'm happy to pass on vacuuming but I now seem up for other duties.

I have been asked by a friend to share my hemming techniques and so along with the final unveiling of the guest towels, there will be a step by step details of what I normally do when finishing off towels or runners.

Once the warp come off the loom, I fire up the serger. (If you don't have one, then a straight stitch on the sewing machine will do. Just adjust the stitch length so the warp ends are all caught and held in place)

In the picture above you can see the towel on the left with its white hem allowance, then there is a narrow stripe of my scrap yarn, followed by a very short section for samples. I was able to squeak out one more towel, so sampling was reduced to a brief showing :) It might be small but it is all you need!

Here they are all cut apart along with my four little mini samples. Next step involves the ironing board. So please excuse the nasty cover as I'm finding it difficult to get a replacement cover for the wider

Rowenta board.

In addition to my

Rowenta steam iron, I use a small slide ruler sold at fabric stores, straight pins. I firmly press the towel and then measure the hems at both ends to ensure they are the same length. I divide the depth of the hem by three and make the first turn.

Then using full steam and a heavy hand, I press it *firmly*. I fold the second turn and ensure it carefully follows the bottom edge of the hem stitching and then *firmly* press again.

In the picture above you can see the folded hem (shown front side up) and ready to be stitched. It stays put after the pressing but I do add some pins to keep it in position during its move to the side table in the living room.

It took a bit of time but all twelve towels finally were turned and ready for the next phase. I was getting a lot of couch time recently and so having these to work on was a nice break! I really enjoyed hand sewing the hems and it seemed to help me feel useful and still working on weaving how ever thin a thread!

I like to use quilters sewing cotton. Its a bit heavier than the polyester thread and less likely to twist. I also feel that I wove a natural fibre towel, so use a natural fibre thread to finish it. Above I'm drawing the thread through the

Thread Heaven to reduce twist and improve the movement of the thread through the cloth. It seems to reduce 'tug' if that makes sense!

I always start at the side fold....

I don't like leaving the side fold open. It leaves the door open for the handwoven fabric to unravel and trail ends out the side and generally look messy. If there is a little of the first cloth fold pushing its way out of line, then I will ease it back into line using the needle.

Once its in place, then I pinch the whole thing with my fingers and start in the end of the fold. I want this part to lay flat so I sew back and forth straight through the cloth.

Then once I get to the main part of the hem, I switch to my running blind stitch. (I think its called this)

Running the needle through the hems fold to 'hide' the thread and at very short intervals, you pop up. I make my stitches very close together as this will be a towel that will be machine washed most likely. I want it to last!

Then you slip the needle through a weft thread or two and through the leading edge of the hem and pull snugly but not so tight as to misshape the appearance in the front. Slip the needle back into the fold and move along. That's it. When you get to the other end, you move down into the side fold and flat sew that closed as well. The pictures above show the non-fancy hem. It works the same for the fancy hemstitched hem allowance too.

The space between the ladders is clearly where you run the thread in the hems fold. So what do I do when the sticky out bit at the side is too large to push back into place with the end of the needle? While I'm not sure if this is the right way, it is what I do....

I gently snip off a portion with sharp scissors, then ease into place with my needle and then flat sew it with extra small stitches to keep it firmly closed!

Sorry for the wack of photos but I feel they can show you the process better than I can explain it. It's certainly not complicated and you should have it worked out after one towel. Feel free to adapt to suit your needs and please share with newbies.

So to review:

- press firmly into thirds with a heavy steam iron

- use small stitches and take your time

Do I ever machine sew? yes! I use it on towels that will be tossed into the wash regularly and doesn't have fancy hemstitching. Sometimes I use hand sewing when I don't want an obvious stitch line running across the cloth as it is visually distracting. So I started out as a new weaver wanting to machine sew everything and slowly over time I have moved more and more to finishing by hand for the obvious benefits it provides of being as secure and less obvious. It does take time to do this work but after what you have already spent winding your warp and weaving, its not a lot of extra time.

Next step is to wet finish them! I placed them in the washing machine and set them for delicate. When they came out I took each one in turn and worked them between my hands and pulled them into shape and and then lay them flat on towels and left them for a couple of hours to absorb moisture.

Back to the ironing board... same disclaimer as before :) I pull and shape the towels giving particular attention to the edges near the hemstitching as it can draw in here. I carefully snip off all weft tails and fire up the iron. Since they are already damp, steam isn't required this time.

I press very firmly! I can lower my board down a bit to make applying pressure from above easier. What we are doing here is to set the threads into their permanent position. Even if the next owner of these towels opts for pressing, they will never need to be done like this again. { Not all weave structures need this or should be ironed this way... its a case by case choice. These are woven with fine smooth threads and reversible pattern} I'm already whispering about needing a

small steam press like Lynnette has for my birthday... wish me luck! I see the store she bought it from doesn't have them listed anymore!

Once the towel is well pressed front and back, I like to fold it into thirds lengthwise, pressing as I go. I'm one of those weird people who actually likes ironing! I'll have to show you my 1950's rolling press some time I scored a few years ago.

Here are the towels with 16/2 beige mushroom weft. Two with ladder stitching and the top one with trellis style. Here's a close up:

Then there's the bronze gold bamboo 8/2 weft:

I had some pumpkin mercerised 16/2 from a friend many years ago:

There were some done in a gun metal gray in 16/2 mercerised cotton:

I also tried an experiment and I'm still trying to decide if I like it. Hub says he does...

That one Maltese cross on the left looks darker than the others but that's just an optical illusion! The body of the towel was woven with mercerised 8/2 cotton for a play of light on white. I had to be very careful when weaving not to lose my place as I would never have worked out where to unweave back to! So they are done at last and what was 8 yards felt more like 16! The hemstitching took a lot of time but I really think these turned out nice and I would be proud to give these as a gifts.

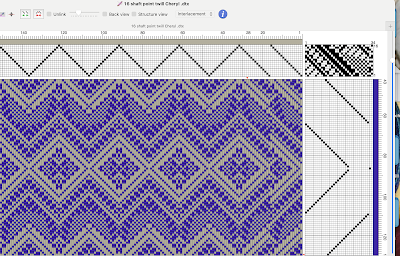

As a bonus for reading this far, I have included here all details of the project plus a copy of the draft. The basic draft came from A Weaver's Book of 8-Shaft Patterns by Carol Strickler and I modified it slightly from there. Click to enlarge the draft or any of the pictures in the post.

Maltese Cross Project

WARP DESCRIPTION

Warp Yarn: merc cotton

Count: 16/2

Color: cream

Cost, source: roughly $7.95 per 250 gram cone; Brassards, Quebec

Warp length: 8 yards

Warp Width: 13.42" at the reed

Set: 36 epi

Reed: 12 dent

Sley: 3 per dent

# Ends: 484 plus 2 floaters

WEFT DESCRIPTION

Weft Yarn: cottons (various) bamboo

Count: 16/2 and 8/2

Colour: white, gold, navy, mushroom

Sources: mainly Brassards

Pattern is taken from " A Weaver's Book of 8 Shaft Patterns" by Carol Strickler

Page 89, 323-4

Project Length:

19" per towel (4" for hems+15" main part of towel)

x 12 towels

-------

228"

12" samples

15" take up

----------

255"

20" loom waste

-------

275" divided by 12 = 22.92' divided by 3= 7.64 yds (rounded up to 8 yards)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Project Width

each pattern group =27 ends x two=54

54 times 8 repeats= 432 ends+ 27 1 repeat to balance+ 24 ends borders= 483

Plus 2 ends for floating selvedges.

Warp wound in two bundles of 242 ends each.

Beamed onto Louet Spring.

Various hemstitching to tart the towels up!