I just got up from the loom where I have made a small, slow start to resuming weaving again. I'm at 30 inches on a scarf on the spring loom. 'Small and slow' as I really do not want to wake up the dreaded lower back and go back to the spasm that had me in its grip and laid up for the past few weeks. Better to let it get used to weaving and build up some strength.

In some ways the time off was good and allowed me to deal with other things that have been waiting for time. I sorted my hand spun yarns and ran them through a yardage counter and so have a better idea of what is there. A time was spent looking over some of my tools and I have parted with some shuttles. They were lovely, but unused so time to find someone who will appreciate their virtues.

I'm the Guild of Canadian Weavers Test Administrator and this is the time of year when I am the go between for the candidates and examiners. So its a busy time and it will be ongoing for at least another 3-4 weeks. Best of luck to all the candidates !

Another benefit of the time off is that you are able to reset your goals and decide what you really want to do with the time at the loom. It can get to be a bit of a treadmill with continual projects and production and that can get old quickly. So a lot of thinking happening on this subject. I've had to readjust physically as I have gotten older and with arthritis and joint issues, but it also makes sense to readjust mentally as well.

This project I'm about to show you is one I had high hopes for and it fell short. Oh, they still look nice and I have no regrets about weaving them but they are not in perfect order due to some issues. They are up for sale but as 'seconds'.

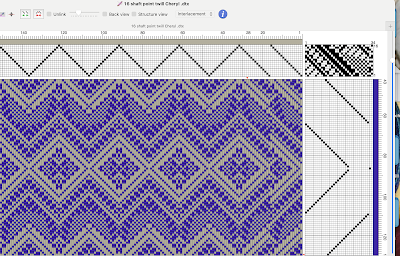

The draft is a 16 shaft point twill that I admired one time and the weaver, Cheryl B. sent me the WIF file some years ago. I set up the Megado with 10/2 mercerized cotton in a colour called 'shell', a sett of 28 epi and I planned for three runners. I wanted to do up nice depth hems with ladder hemstitching so they could be displayed either side.

The pattern is quite ornate and busy and so I chose more sedate colours to fit any decor. It would be great with bright bands of colour and take on a festive look but that would be for a future project. This weft was slate 8/2 tencel.

This is the back view as marked by a maker's tag.... more on this in a minute. The finished size on this runner is 16 by 44 inches.

The next runner was also 8/2 tencel weft but this time in taupe. I quite like this colour and this is the front view....

... and here is the back view.....

Maker tags went on all the back views.

Here you can see both sides together. It would have been nice to be able to pick which side you like better ( and maybe for some person, they still will.) This one measures 16 by 43 inches finished.

The third runner was much longer at 16 x 71 inches but I wanted a cloth for a larger table or armoire. This time I used 10/2 mercerized cotton in a colour called 'sponge' ( darn silly name!) Its a light silvered green and quite pretty.

Front view and as you can see, its long! I laid it out lengthwise on our long table but it looks boring as heck. I did my best with lighting but..... here's the back view:

A close up of the hem and ladder stitching which I enjoy doing. Good thing too as it take a long time !

There appears to be a line warp wise on the right side.... but its an illusion. No threading error but where three ends were sleyed together right at the point and stayed together !

So what went wrong? Everything appeared fine when I took them from the loom but when I flipped them over, random rows on the back side had skips. Sometimes not all the way across, and some times over so many inches. Not sequentially like a treadling error. That I could blame on the Megado's compu-dobby but not this time.

The front look just fine but on the reverse there were these random skips. The sett and my eye sight meant I wasn't the least bit interested in trying to needle weave a fix. That, plus the many rows that needed to be done never even made that an option for me.

So I folded them up and they sat in a 'time out' pile while I thought things through. Eventually I decided that they are fine if you view them one side only..... and be honest about the flaw. Not everyone is obsessed with perfection as some weavers are. (Yes that was hard to say as test administrator!)

So what caused this issue? I found myself giving the loom side eye and not feeling the love anymore. Which is silly as its a tool, a great big tool and issues are either mechanical or computer related. The pattern of skips were too random to be a computer glitch so I started to look at mechanical issues.

It took some time but I found it. The shaft cords on the Megado look like a wall of cords as the shafts are all close together but when you look closer you see that the texsolv cord comes down and sits in a little slot at the end of every shaft, on both sides. A couple of the shafts had cords that sat outside the slot. Its hard to see unless you are looking for it.... and I know that I will never forget to check ever again! The cord is needed to fit in the slot to ensure the shaft lifts up and sets back down again smoothly. Not in the slot means the shaft can float by about 1/4-1/2 inch and so the shuttle skips some threads. I have always made sure the extra heddles don't bunch up to prevent floating shafts and I arrange them alternating brick style. During threading you can be pulling and tugging at the shafts and heddles and I guess they slipped out. Its a wonder this didn't happen sooner in my 9 years with this loom.

Always something new to learn and I think I might work up a check list like an aircraft crew works from and tick some 'take off' boxes for future projects.

The runners are hemmed, pressed and looking fine. They are fully declared as seconds and being sold at a reduced price. Someone will love them just as they are.

A final note: I'm hearing that some weavers are more or less tossing their new weaving into the washing machine and dryers, or sometimes just smoothing damp and wrinkly and letting dry overnight. This will deep set the wrinkles into your cloth and its just about impossible to remove them.

Even my kitchen towels, that eventually go into the washing machine and dryer, start off by being hand washed and line dried over a rack. Then, while still slightly damp, they are pressed smooth to set the threads into their final positions. What a weaver does in the finishing stages is nothing at all like an end user will do going forward. Its a stage that is as important as the planning and weaving stages and all the other steps in between. If you are serious about making beautiful cloth, then get comfy with hand washing and your iron. It makes a world of difference to your presentation !

16/2 cotton & 40/2 linen, washed and pressed!